Rᕕ

Size: a a a

2021 August 15

пленку же снимаешь

Rᕕ

бля круто

Rᕕ

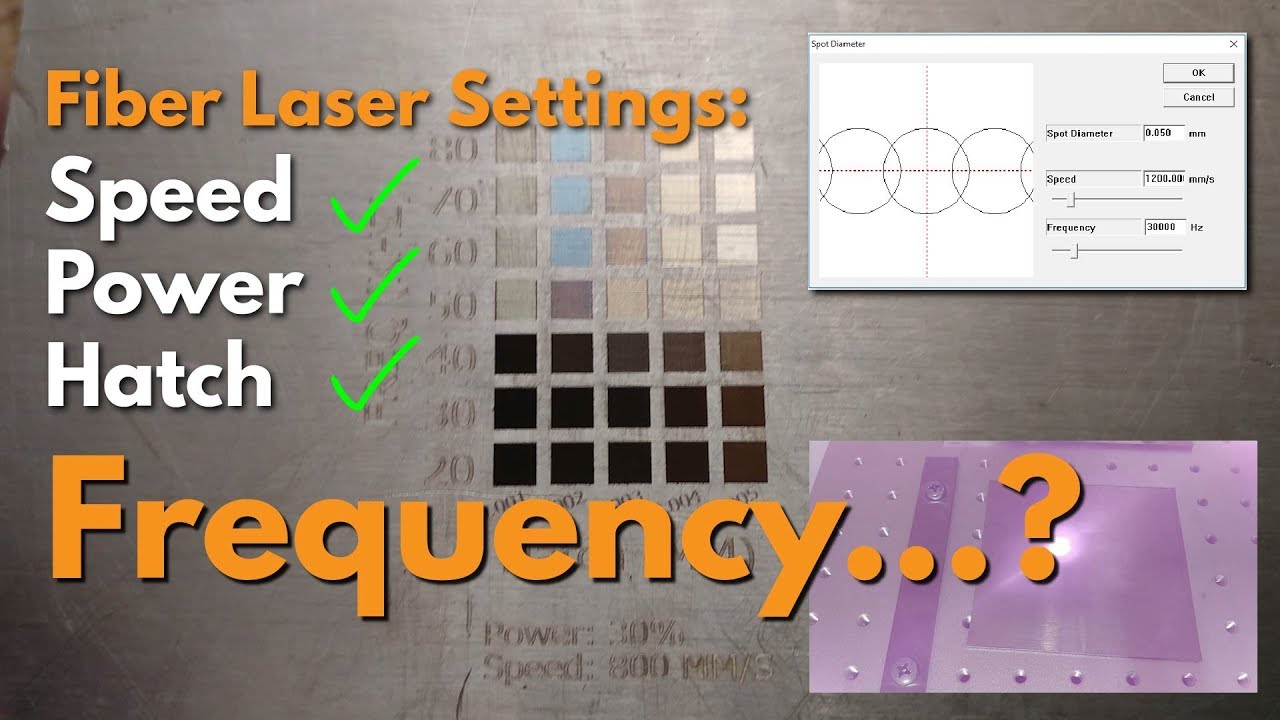

How color laser engraving works

The principle behind laser color engraving is surface oxidation. Scientifically, many material surfaces react in the air to form thin oxide layers. When the surface of a material is heated using a laser beam, it forms a thin oxide film. The actual thickness of this film is achieved by altering the scanning velocity, power, and line spacing. Other essential parameters for the technology include marking direction, marking speed, focal spot diameter, pulse length, and repetition rate.

Once a constant material surface temperature has been maintained, a uniform color can be created. The thin oxide layer will grow in thickness until it forms a thin film effect. This is what determines the reflection of white light and hence the appearance of other colors. A thick oxide layer is beneficial because it protects the material against corrosion and scratching. For acrylic, color laser engraving is achieved through the addition of a color dye powder. This begins with traditional engraving then pressing a special powder on the engraved parts using a laser machine.

The principle behind laser color engraving is surface oxidation. Scientifically, many material surfaces react in the air to form thin oxide layers. When the surface of a material is heated using a laser beam, it forms a thin oxide film. The actual thickness of this film is achieved by altering the scanning velocity, power, and line spacing. Other essential parameters for the technology include marking direction, marking speed, focal spot diameter, pulse length, and repetition rate.

Once a constant material surface temperature has been maintained, a uniform color can be created. The thin oxide layer will grow in thickness until it forms a thin film effect. This is what determines the reflection of white light and hence the appearance of other colors. A thick oxide layer is beneficial because it protects the material against corrosion and scratching. For acrylic, color laser engraving is achieved through the addition of a color dye powder. This begins with traditional engraving then pressing a special powder on the engraved parts using a laser machine.

i

Переслано от Андрей Чеботарев...

Ф🌶

Интересное

i

Сверхзвуковая скорость разве как то влияет на радиопередачу ?

D

Думаю никак не влияет

D

Вопрошающий тормоз наверно

i

Двоешник

D

100%, как я прям), когда что-то пытаюсь сделать

AF

уверен что он отличный работник творческой специальности а физика ему в школе не нужна была потому что нахуй она

AF

но вы все ржете а он получит в этом месяце овер дохуя бабок потому что всирает истину толпе

AF

окей гугл доходы Бутина

AF

или как ее там эту "шпиенку" продажную

AF

ну и надо както дать шанс ущербным технарям почувствовать себя полезными, пусть потешат чсв

D

Происходит какая-то деформация знаний(дебилизация) уже не один год наблюдаю

AF

AV

его разум недостаточно страбон?